Hi Shano,

I have taken the body of an Excel Chassis twice this year as part of my mix and match total restoration project. I am by no means an expert, (just look at some of the questions I have had to ask on this forum), but it is something a mere mortal can do.

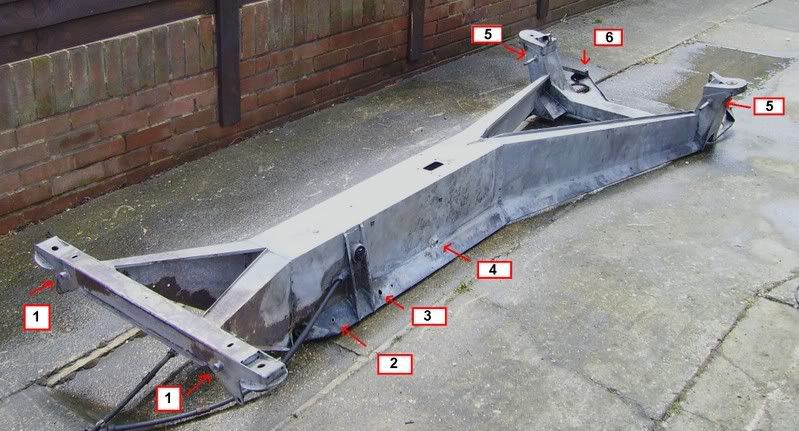

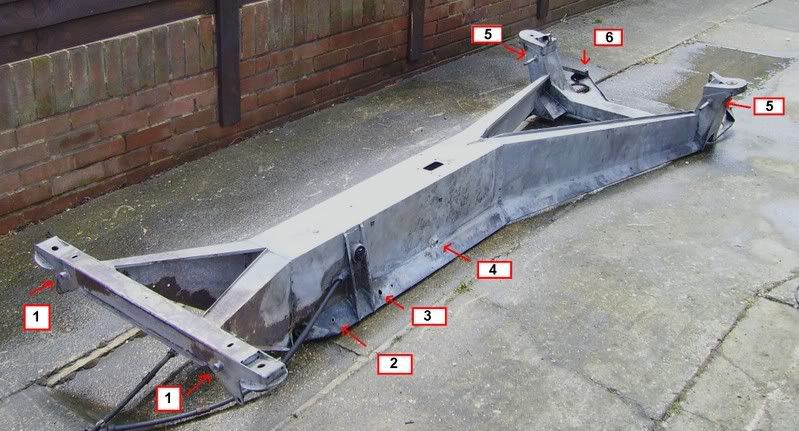

Both of mine are early Excels, and the fixing bolts have been as shown in the picture below, (all are in matching pairs either side of the chassis, but not all could be shown on both sides in all cases). Numbers in brackets show the locations.

Two in the boot within the spare wheel well that go horizontally into the back of the chassis. (1)

Four in the passenger foot well area. (2) & (3)

Two that hold the seatbelt clamp to the transmission tunnel. (4)

Two through inside the engine bay that go into the suspension turrets. (5) I haven't managed to remove one of these yet without snapping the bolt in the process.

Two that hold the front anti-roll bar two the chassis (and then body). (6)

So, that is 12 bolts altogether.

Let the above picture be a warning to you, as your chassis might look as grim as mine did! This picture was taken after many hours of effort with a wire brush and high pressure hose to expose the chassis underneath. It will be impossible to resist the urge to strip it down and then clean and paint it if you get to this stage....

I don't want to teach you to suck eggs, but if you are taking the body off, I would advise:

1) You need more space then you would at first imagine.

2) 12 bolts seems straight forward, but this is an involved task that will take a long time.

3) You are bound to discover horrors that need urgent fixing, expect your repair bill to rocket skywards!

If you need any more advice or pictures and tales of how I bodged it, just ask!

Chris